They say there are several ways to kill a cat, but when it comes to something critical or of high importance such as a leaking roof deck, we always turn to our favorite tried and tested solution – a cement mix fiber reinforced crystallizing material that seeks out the microscopic pores and cracks and seals water out.

They say there are several ways to kill a cat, but when it comes to something critical or of high importance such as a leaking roof deck, we always turn to our favorite tried and tested solution – a cement mix fiber reinforced crystallizing material that seeks out the microscopic pores and cracks and seals water out.

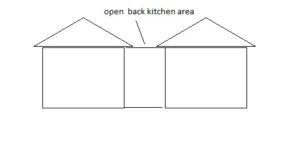

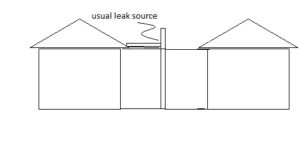

Even if you waterproof your roof deck during construction, over time, the usual cement mix material during construction will fail, due to several factors such as earth movements, sun exposure – which causes cement to wear out, constant hammering of people walking around the deck during parties, etc., so it is inevitable that over time, leaks start to occur.

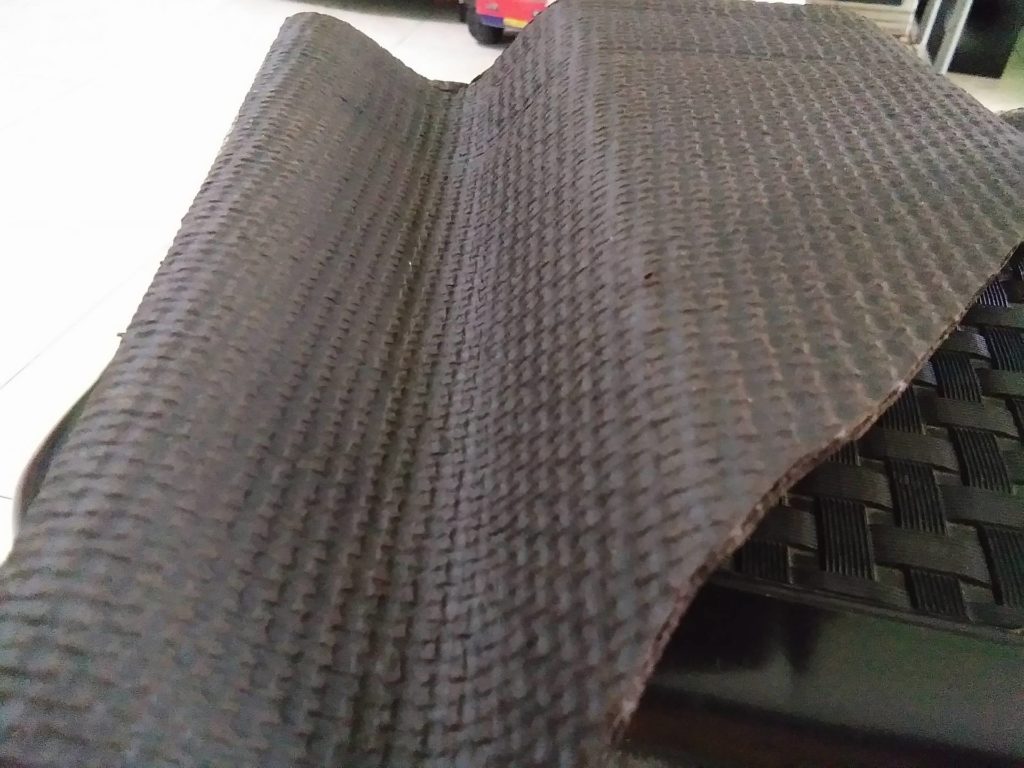

There are a lot of materials out there – from cheap ones, not so cheap ones, and really costly ones such as the rubber cure, but as we are here in the Philippines, we always seek out that material or method which is cost effective, not so cheap, not so costly, but highly effective – a cement based fiber reinforced acrylic polymer that is mixed with portland cement.

The material we use is a flexible, fiber-reinforced, modified high-grade acrylic polymer that is mixed with

portland cement to provide superior water sealing of your roof deck. It has great advantages and benefits such as superior water impermeability, highly compatible to concrete substrates since it is cement based, high water vapor transmission, superior UV resistance due to the high grade polymer and cement, monolithic, tintable (can be mixed with different colors), moves with concrete as it is fiber reinforced, bridges hairline cracks, excellent adhesion to concrete due to its chemical and mechanical bonding properties, releases retained water vapors in concrete, prevents blistering, no joints and laps, minimizes painting cost.

Feedback