When it comes to constructing houses and building structures, ensuring strength, durability, and stability is of paramount importance. One essential component that plays a significant role in achieving these qualities is the versatile I-beam. Let’s explore the use of I-beams in the creation of robust and reliable structures.

What are I-Beams?

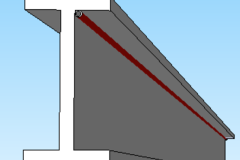

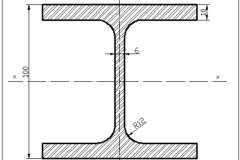

I-beams, also known as universal beams or wide-flange beams, are structural steel members characterized by their distinctive “I” shape. These beams consist of a vertical web connected to horizontal flanges at the top and bottom. The unique design of I-beams enables them to distribute weight evenly along their length, making them ideal for bearing heavy loads and providing structural support.

Strength and Load-Bearing Capacity:

I-beams are renowned for their exceptional strength and load-bearing capacity. The vertical web of the I-beam resists shear forces, while the top and bottom flanges handle bending moments. This distribution of forces allows I-beams to efficiently carry significant loads without excessive deflection or structural failure. Whether it’s the weight of multiple floors, roofing systems, or other heavy elements, I-beams provide the necessary support for a sturdy and reliable structure.

Structural Versatility:

I-beams offer unparalleled versatility in construction applications. Their standardized dimensions and wide range of sizes make them compatible with various architectural designs and structural requirements. Whether used in residential, commercial, or industrial construction, I-beams can be tailored to fit specific needs, such as longer spans or higher load capacities. Architects and engineers can select the appropriate size and shape of I-beams to ensure optimal structural integrity and safety.

Efficient Material Utilization:

One of the notable advantages of I-beams is their efficient use of material. The design of I-beams concentrates material at the outer regions where it is most needed to resist bending forces, resulting in a structurally efficient and lightweight beam. This feature not only reduces construction costs but also allows for more flexibility in architectural design.

Construction Process:

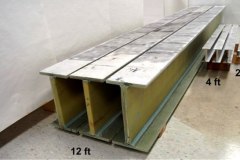

The manufacturing process of I-beams typically involves hot rolling, where steel billets are heated to high temperatures and shaped into the desired “I” profile. This process enhances the mechanical properties of the steel, such as its strength and toughness, making I-beams even more suitable for demanding construction applications. The standardized dimensions and quality control during production ensure consistency and reliability in the final product.

Applications in House and Building Construction:

I-beams find extensive use in various aspects of house and building construction. They are commonly employed in the creation of load-bearing walls, floor and roof systems, and structural frameworks. Whether it’s supporting vertical loads in multi-story buildings or spanning wide distances in bridges and industrial facilities, I-beams provide the necessary strength and stability to ensure the integrity of the structure.

In the world of construction, the utilization of I-beams has revolutionized the way houses and buildings are designed and built. Their distinctive shape, exceptional strength, and efficient material usage make them indispensable in creating structures that can withstand heavy loads and environmental stresses. From residential homes to towering skyscrapers, I-beams play a vital role in ensuring the durability and reliability of modern construction projects. With their versatility and standardized dimensions, I-beams continue to be a cornerstone of the construction industry, providing architects and engineers with a robust and efficient structural solution.

The use of I-beams in house and building construction offers additional benefits beyond strength and durability. These beams facilitate open floor plans by eliminating the need for load-bearing walls, allowing for more flexible and spacious interior designs. With the support of I-beams, architects can create expansive, light-filled spaces that enhance the overall aesthetics and functionality of the structure.

I-beams play a vital role in roofing systems, where they provide structural support for heavy loads such as snow, equipment, or solar panels. By incorporating I-beams into the roof design, builders can ensure the safety and longevity of the structure, even in areas with significant snowfall or adverse weather conditions.

In industrial and commercial construction, I-beams are used extensively in the creation of large-span structures such as warehouses, factories, and shopping centers. These beams allow for the construction of wide, open spaces without the need for interior support columns, providing flexibility for various layouts and maximizing usable floor area.

In retrofitting and renovation projects, I-beams are often utilized to reinforce existing structures, strengthening their load-carrying capacity, and improving overall stability. By strategically installing I-beams, builders can address structural deficiencies, support additional floors, or remove load-bearing walls during renovations, providing flexibility in transforming old spaces into modern, functional environments.

The use of I-beams in house and building construction is fundamental for creating strong, reliable, and visually appealing structures. Their exceptional strength, load-bearing capacity, and efficient material usage make them a preferred choice among architects and engineers. From supporting floors, roofs, and walls to facilitating open floor plans and spanning wide distances, I-beams play a pivotal role in shaping the modern construction landscape. As technology and construction techniques continue to advance, I-beams will undoubtedly remain a cornerstone in the industry, contributing to the creation of innovative, safe, and sustainable structures for generations to come.

Feedback