Here in the Philippines there are major stumbling blocks when trying to build an ICF Insulated Concrete Forms home.

The stumbling blocks are: 1. Local building code requires columns and beams; 2. Its very hard to find a concrete conveyor. Ready mix concrete companies here usually only have high pressure pumpcrete; 3. Workers need in depth training in ICF style construciton.

Americans and Canadians and other home owners coming from cold countries do require insulated homes when they decide to settle in the Philippines to be able to save on air con electricity bills. Their homes need to be insulated from the outside heat so as not to overwork their air conditioning systems.

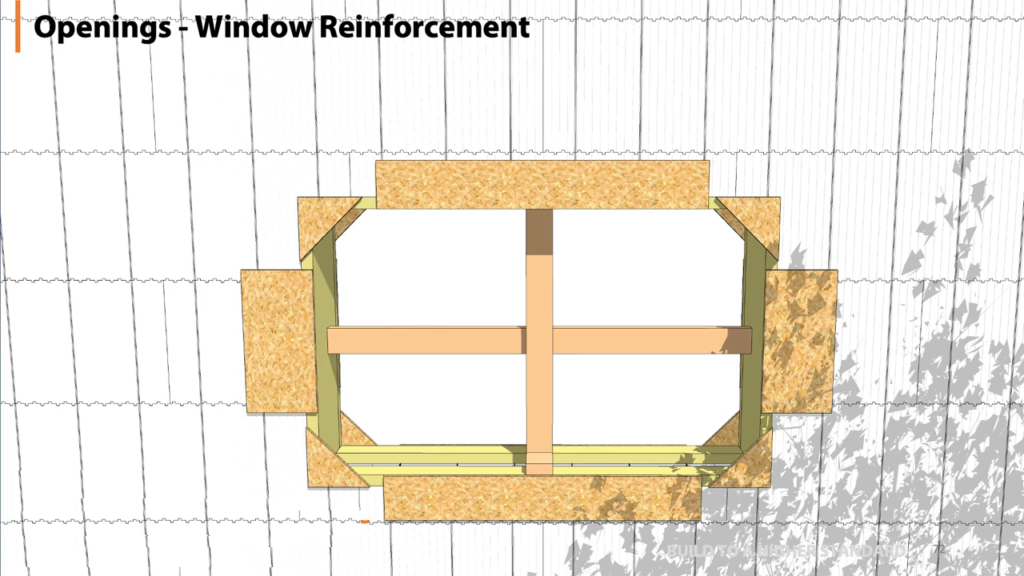

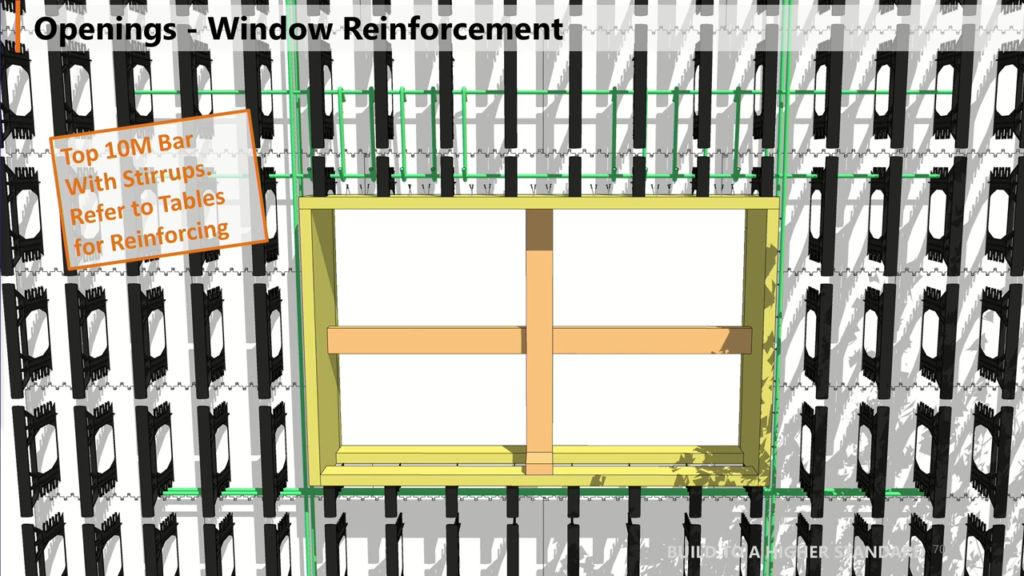

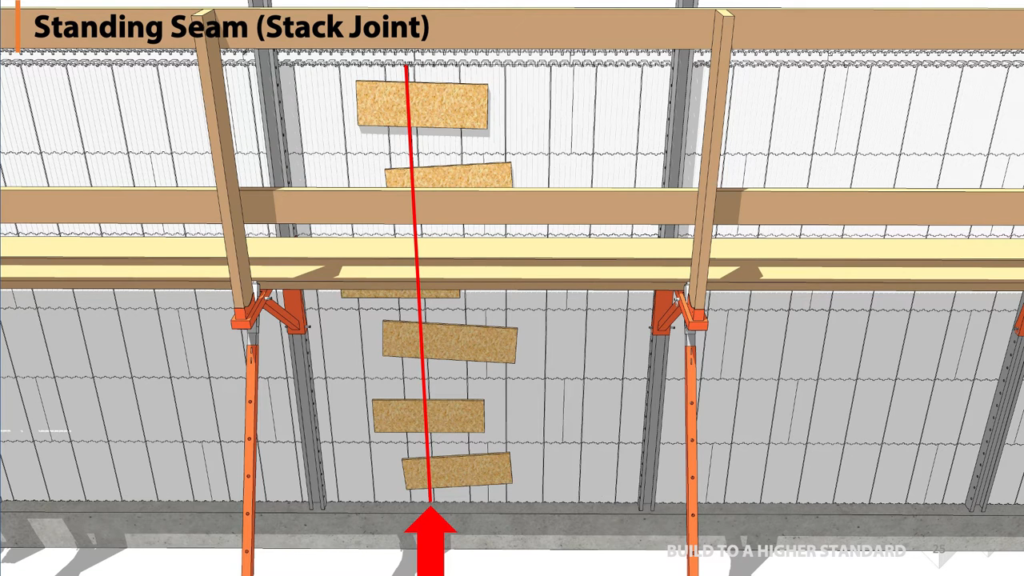

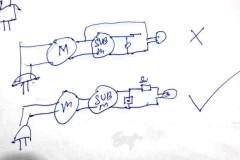

The Philippine building code require columns and beams in contrast to the original American and Canadian ICF construction style that don’t require columns and beams since the walls are solid concrete making them excellent load bearing walls. So the easiest way around this is just to build the columns and beams but insulate them like you would an ICF wall – EPS on both sides of the solid pour topped with drywall. Make sure though that you don’t build the beams of the second floor slab ahead – you have to wait for the ground floor walls to be finished so you can just build your second floor slab beams on top of your cured ground floor insulated walls.

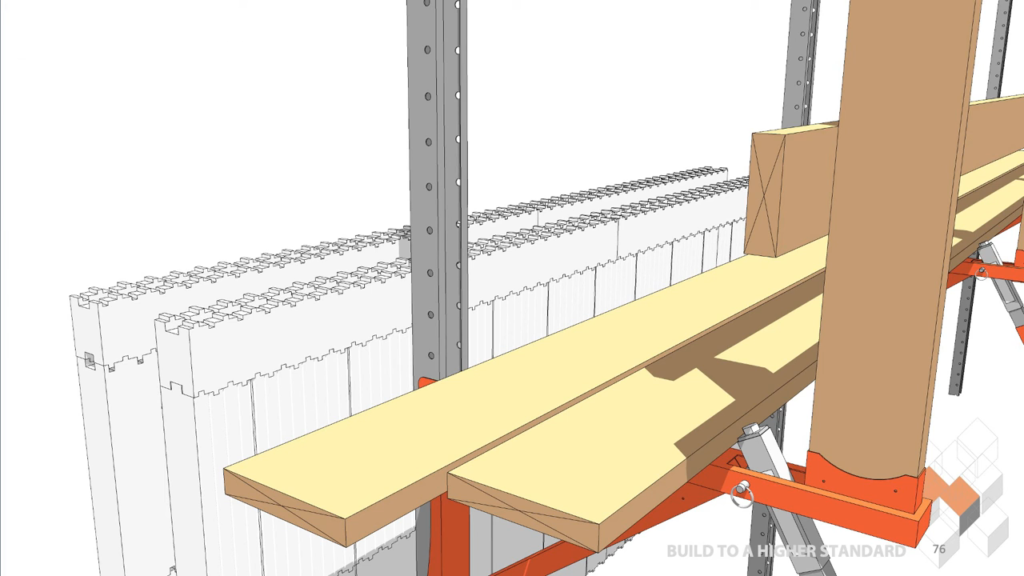

Another stumbling block is the unavailability of a concrete conveyor – a concrete conveyor is one that delivers liquid concrete from the truck without the pressure from pumpcrete / concrete pump. It is important that liquid concrete be delivered without the high pressure so as not to destroy the ICF concrete forms since it is made of light ICF. The solution for this if you cannot find a concrete conveyor is to just use wide ICF forms and hold it together with tie rods – a piece of metal that holds the two insulation forms and tie it outside on the plywood form surface. This will require that your drywall top needs to be pre installed and to secure your drywall – simply use long screws that await in the concrete core area so that it holds when the concrete cures. After curing, simply cut the tie rods below drywall surface level and cover it with spray EPS.

The final stumbling block is the scarcity of workers with ICF training. This is where your training ability will shine. You have to design your training in such a way that the workers will see the benefits and the rationale of an ICF or insulated home, so that they will have the ICF mindset as they slowly build the house. It is also advised that your skilled workers be of the younger age bracket as younger people are usually adept to change compared to their older counterparts.

If you are planning to build an ICF or insulated home here in the Philippines, simply email us your rough house layout and a photo scan of your lot sketch plan and a google snapshot of your lot location to finefinishcebu@gmail.com or to topcebucontractors1@gmail.com

Pleased to update to potential interested parties the recent update on this house in Valencia Negros Philippines. The second floor walls are now done. In the attached pictures below you will see how the structure now looks, just lacking the roofing and wall finishing. You can see the 2 inch EPS insulation on both sides of the beams and walls in the pictures showing the freshly poured walls and beams. A video of the actual pour will also be added later on. Enjoy the pics and the video and do let us know if you are interested in building an ICF house in the Philippines.

See the video of the pour here:

Feedback