Got a call for help from one of the users of this relatively new bitumen based cellulose roofing material called Onduline Roofing Systems from France. This roofing material is one of the recommended roofing systems by Paramount Realty in one of their communities – Fonte Di Versailles in Minglanilla town. Since the community is very close to the beach, this onduline roofing system, since it is bitumen based, is meant to withstand the corrosive properties of the nearby beach.

Got a call for help from one of the users of this relatively new bitumen based cellulose roofing material called Onduline Roofing Systems from France. This roofing material is one of the recommended roofing systems by Paramount Realty in one of their communities – Fonte Di Versailles in Minglanilla town. Since the community is very close to the beach, this onduline roofing system, since it is bitumen based, is meant to withstand the corrosive properties of the nearby beach.

Unlike the Philippine popular and cheaper metallic roofing systems, the onduline material, as it is bitumen based and made of cellulose materials, is meant to withstand corrosion, is quiet-especially during rains, lightweight, and is a good thermal shield from the heat of the sun. Upon checking at the hardware, onduline is also relatively affordable-about only 30% more expensive than the ever popular metallic color roofing systems. This material now seems better than the metallic roof.

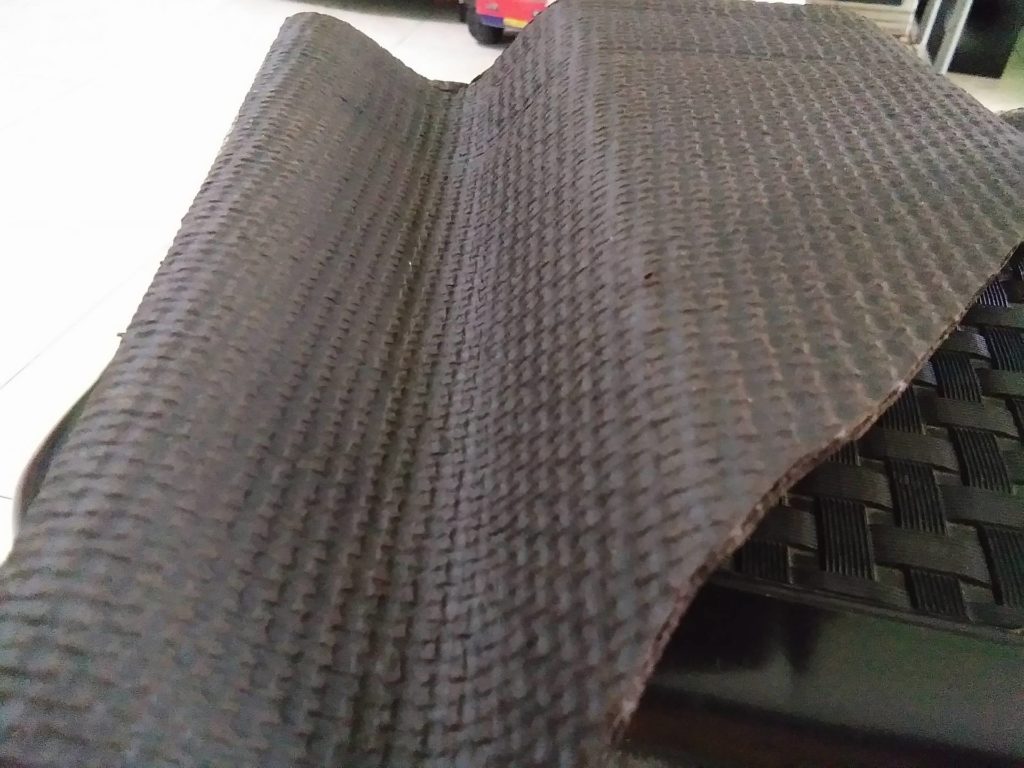

Upon checking at the owner’s house, there is one weakness I found in this material which I believe still makes the metallic roofing better that this onduline at least in one aspect – which could mean the metal roof will still be preferred just due to this one aspect. That one aspect is that it cannot withstand human weight. It easily gets deformed when being stepped upon. This is the reason why from just one leak, it is now 3 major leaks for the owner. The leak problem started right from the beginning with just very little water coming in. The owner stated that it was just due to the installers not following the prescribed overlaps. As you may know, some contractors do not follow the prescribed over laps or ridge gaps to try to save just a little. But this will be a big problem for the house owner. Going back, the little water intrusion over time has increased, as strong winds does deform the onduline material and over time the gaps within the overlaps increase. The leaks increased from just one, now 3 when they asked carpenters to fix the original leak. The workers had to step on the material while fixing the original leak. Their weight had caused the ridges to get deformed and the strong winds had further aggravated the deformity and increased the gaps thus allowing water to come in.

When using the onduline, I highly recommend you don’t step on it. When trying to fix a leak, put a 3/4 inch plywood on top for you to step on to distribute your weight over the onduline sheets. When leaks occur due to gaps due to strong winds, you will need to replace that sheet if it cannot be fixed with just tightening the ‘speedy screws’ holding the sheets – my ten cents.

9 comments

Skip to comment form

Therefore there should be an undersheet of material when using onduline. undersheet of plywood and metal plain sheet so as to not damage the roof and prevent water entering in to your house. thus making the system more costly.

Author

Yes better to have undersheet like plywood or metal…

Admin

how flammable is onduline roofing, esp in Philippine conditions?

I found this in an internet review of this type of roofing system.

Thank you.

Author

Onduline is not totally fire proof but it is fire resistant or fire retardant – which means it is not easy to burn it – or you cannot use it to fuel fire… But for roofing purposes – it serves well… It is just like the popular asphalt shingles…

hello,you have bitumen?

Author

If you meant bitumen / asphalt shingles yes… We have from US, Canada, China, and Local…

Author

You can send your pdf roof plan, if you have, to finefinishcebu@gmail.com

helo,you have bitumen ?

Author

Yes – asphalt / bitumen shingles…